Honeywell Debuts Robotic Unloader for Trucks and Trailers

Tech giant Honeywell announced a new automated robotic solution for unloading truck trailers and shipping containers at distribution centers.

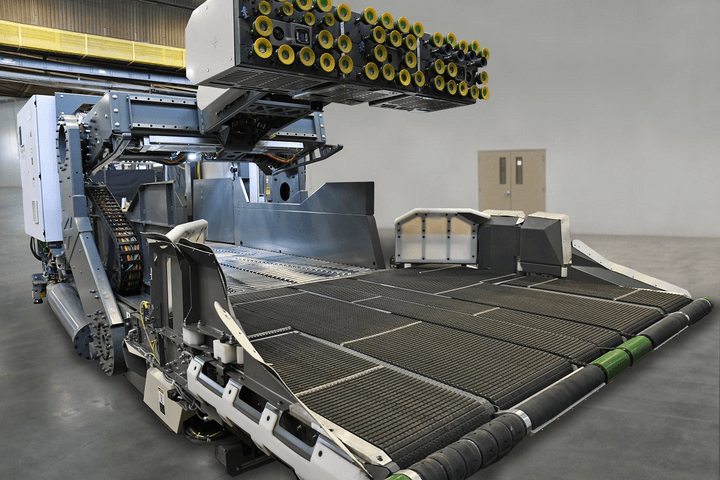

Photo courtesy Honeywell

Will robots unload your trucks one day? That’s the future according to tech giant Honeywell, which announced a new automated robotic solution for unloading a wide range of packages from truck trailers and shipping containers at distribution centers.

According to the company, the robotic unloader uses artificial intelligence to operate fully autonomously inside of a trailer, which significantly reduces the manual effort required to operate receiving docks for retail merchandise and parcel distribution centers. This new Honeywell Intelligrated smart robotics offering will help customers improve workplace safety, reduce staffing challenges and minimize damage to packages.

“For distribution center workers, unloading packages is labor-intensive, physically demanding and injury-prone work that is often subject to extreme temperatures. These factors lead to low employee satisfaction and high turnover – as much as 36%, according to the U.S. Bureau of Labor Statistics,” said Matt Wicks, vice president of product development at Honeywell Intelligrated, in a release. “With our robotic unloader, we are using advanced machine learning to allow workers to remove themselves from the extreme environment and to oversee multiple unloading machines, increasing productivity and improving safety.”

Honeywell’s new robotic unloader drives into a trailer or container and uses machine vision to identify various package shapes and sizes so it can determine the optimal approach to unloading. A robotic arm with a series of small suction cups conforms to the package shape to gently extract it from the stack. A conveyor below the arm can serve as a sweeper for packages to move them out of the trailer.

“In real-world applications, we are unloading a rate of up to 1,500 cases per hour and helping companies maximize throughput safely and efficiently,” said Wicks. “We’re working with Carnegie Mellon University to deploy advanced machine learning to expand the robotic capabilities with improved 3D vision, perception, processing power and gripping.”

Unlike other unloading solutions, Honeywell said, its Intelligrated unloader is fully autonomous and is designed to work within existing fleets to eliminate the need for costly configurations or modifications to trailers or standard shipping containers. The unloader features patented gentle mechanisms to minimize package damage without impacting performance.

For nearly three decades, Honeywell Intelligrated has developed robotics solutions for warehousing operations and is a certified robot integrator by the Robotic Industries Association. In addition to its collaboration with Carnegie Mellon University’s National Robotics Engineering Center, Honeywell Intelligrated is also combining efforts with Fetch Robotics to deploy autonomous mobile robots to distribution centers.